Industrial Coffee Grinder vs. Personal Grinder: Key Differences Outlined

Industrial Coffee Grinder vs. Personal Grinder: Key Differences Outlined

Blog Article

Industrial Coffee Grinder Guide: Increase Effectiveness and Top Quality

In the competitive landscape of coffee manufacturing, selecting the ideal industrial coffee mill plays an essential function in boosting both performance and product top quality. Comprehending the subtleties of different grinder kinds and vital functions-- such as adjustable work settings and durable building-- can dramatically affect the last flavor account of the coffee. Furthermore, the optimization of the grinding process, combined with thorough maintenance, is vital for sustaining performance gradually. As we explore these vital components, it comes to be evident that the implications prolong past mere devices option, affecting overall business success in manner ins which require closer assessment.

Comprehending Grinder Types

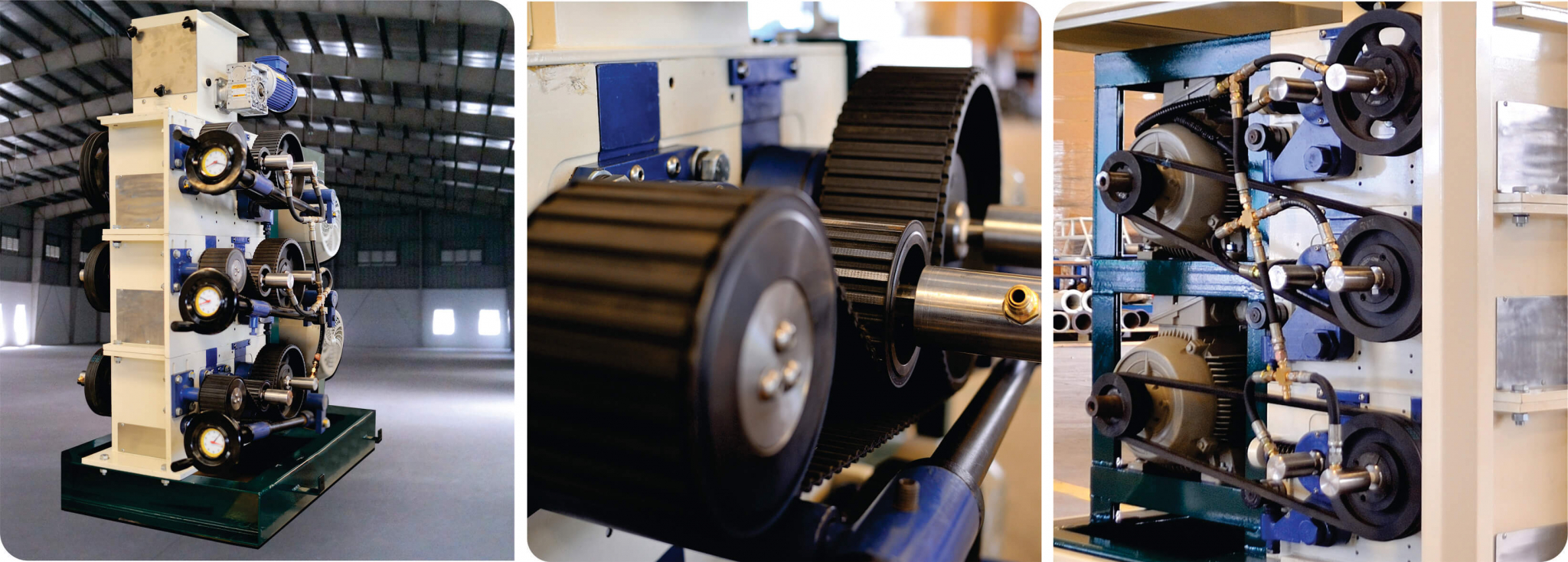

When selecting an industrial coffee mill, understanding the various kinds offered is critical for maximizing both taste extraction and operational effectiveness. Both main kinds of grinders are blade mills and burr mills. Blade grinders make use of sharp blades that chop coffee beans into irregular sizes, bring about uneven removal and potentially unfavorable tastes. While blade mills are often extra ideal and cost effective for small procedures, they are usually not suggested for industrial use.

Ultimately, selecting the best kind of grinder is important to maintaining quality and efficiency in coffee manufacturing, making it vital for organizations to purchase top quality burr mills for ideal results.

Key Features to Think About

Choosing a commercial coffee mill needs cautious consideration of numerous crucial attributes that can considerably affect both performance and the general coffee experience. One of the main facets to evaluate is the grinding system. Burr mills are generally chosen over blade mills, as they provide a consistent work dimension, which is critical for optimal extraction and taste.

An additional vital attribute is the mill's capability. A versatile grinder with multiple setups permits you to tailor the work dimension to various brewing approaches, enhancing the coffee's flavor profile.

The construction material additionally plays a role in resilience and maintenance. Stainless steel components usually supply durability and are easier to cleanse, which is vital for maintaining health standards. Finally, review the grinder's noise level, specifically in an active café or manufacturing environment, where extreme sound can be turbulent. Purchasing a grinder that balances these attributes can considerably improve both functional efficiency and the quality of the coffee offered.

Optimizing Grinding Process

To accomplish the best outcomes in coffee preparation, optimizing the grinding process is vital. The work dimension considerably affects removal, taste, and total top quality of the made coffee.

Additionally, keeping an eye on the grinding speed can enhance the procedure. Slower grinding usually creates less heat, protecting fragile tastes and fragrances. Conversely, faster grinding might produce excessive heat, adversely influencing the coffee's top quality.

Upkeep and Care Tips

Proper maintenance and treatment of commercial coffee grinders are necessary for making sure optimum performance and longevity. Normal cleansing is the foundation of maintenance; deposit build-up can influence flavor and grinding effectiveness. It is recommended to cleanse the mill after each use, wiping down the outside and removing any type of coffee grounds from the burrs.

In addition, inspect the grinding burrs for deterioration. Boring burrs can jeopardize work consistency, so they need to be replaced as necessary. Industrial Coffee Grinder. Periodically calibrating the mill is likewise crucial, as this keeps the desired grind size for various brewing techniques

Lubrication of relocating parts must be carried out according to the supplier's requirements, as this decreases rubbing and lengthens the life of the devices. It is necessary to utilize food-grade lubricants to guarantee safety and security and compliance with health regulations.

Finally, keep the grinder in a completely dry and secure setting to avoid corrosion and deterioration. By sticking to these upkeep and treatment ideas, drivers can boost the performance of their industrial coffee grinders while making certain high-grade output and prolonged useful reference functional life.

Return on Investment Analysis

Assessing the roi (ROI) for industrial coffee mills is critical for services looking for to optimize their coffee manufacturing capabilities. A comprehensive ROI evaluation aids establish the financial stability of buying high-grade grinders, allowing companies to weigh the initial costs against potential gains.

Assess the acquisition cost of the mill, consisting of setup and any kind of required adjustments to existing infrastructure. High-performance grinders usually lead to minimized grinding time and enhanced throughput, which can substantially enhance performance.

Additionally, consider the influence on item top quality. Industrial Coffee Grinder. Superior mills generate a more regular work dimension, which can boost taste accounts and customer complete satisfaction, eventually driving sales. By increasing the high quality of the end product, organizations can validate greater rates, click here for more bring about enhanced income

Verdict

In summary, a commercial coffee grinder plays a crucial duty in enhancing both effectiveness and product quality within coffee manufacturing. Ultimately, the strategic financial investment in a dependable grinder contributes considerably to enhanced earnings and competition in the coffee market.

In the competitive landscape of coffee production, choosing the right industrial coffee mill plays a critical role in enhancing both performance and item high quality. The two key kinds of mills are blade grinders and burr grinders. Within the burr mill category, there are level burr grinders and cone-shaped burr mills, each with its advantages. Burr grinders are usually liked over blade grinders, as they give go to my site a constant grind size, which is critical for ideal extraction and taste.

In recap, a commercial coffee mill plays a crucial duty in boosting both effectiveness and item top quality within coffee manufacturing.

Report this page